Excellence

and Prowess

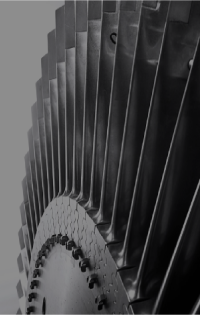

Manufacturing Excellence

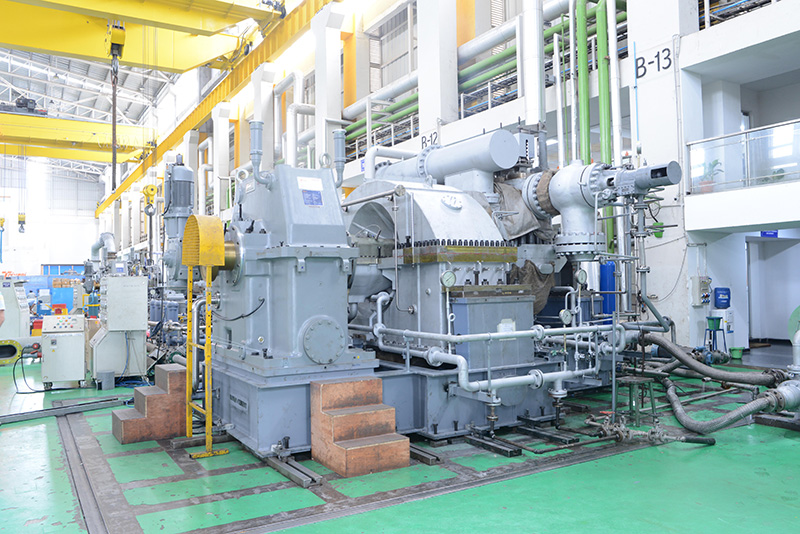

World-class integrated manufacturing and testing facilities with best-in-class machinery and equipment. Our two manufacturing facilities are equipped with state-of-the-art machinery and the latest software for seamless manufacturing of all critical components and assembly in-house.

Our infrastructure includes world-class testing facilities, that guarantee product excellence through comprehensive validation of design meeting the most demanding international quality standards. Besides tools and machinery, our facilities are equipped with IoT-enabled Industry 4.0 manufacturing practices that enable us to streamline activities in this digital era at every stage of the production process.

State-of-the-art Infrastructure

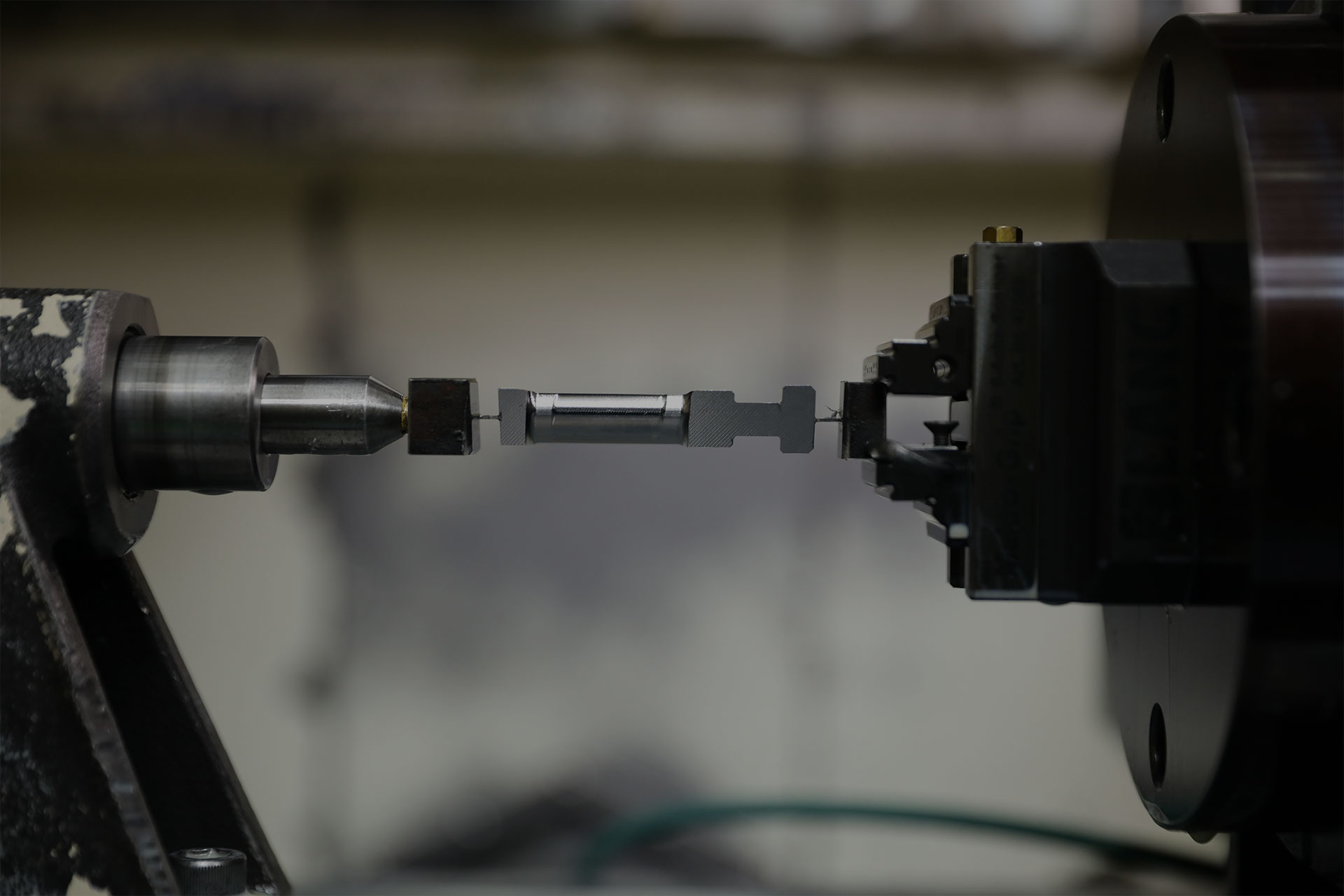

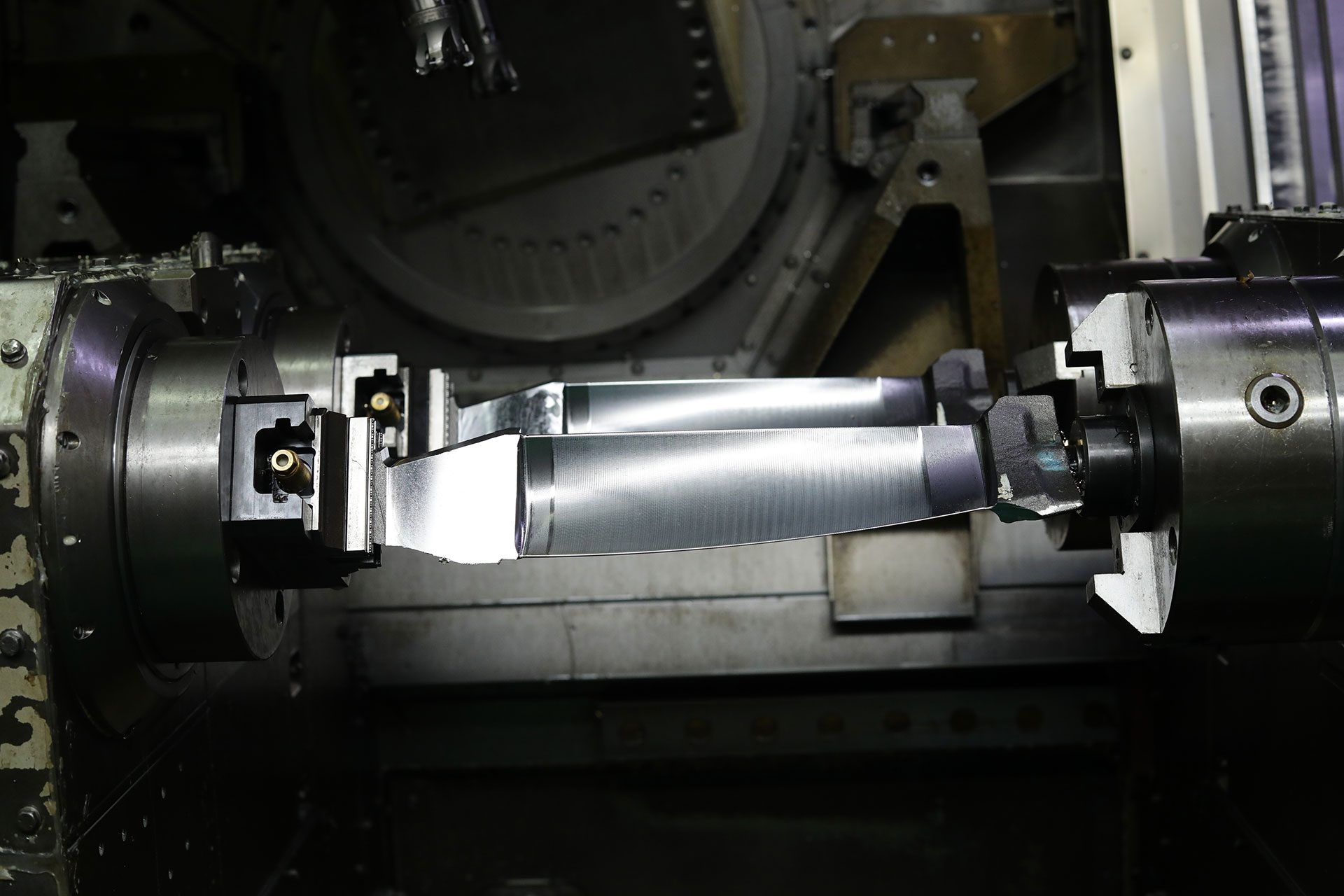

Our manufacturing capabilities are powered by various high-end machinery and equipment, which include:

World-Class CNC Machines

High Speed Vacuum Tunnels

Our Key Strengths and Capabilities

Our integrated steam test facility with high pressure and temperature boilers are capable of handling condensing and back pressure Steam Turbine Generators (STGs) up to 100 MWe

Our test beds are equipped with crucial inputs and provide options for customers to live stream the test bed SCADA screens with all relevant parameters, to facilitate remote inspection

Contact Reach out to us