Delivering

Excellence

Sustainability

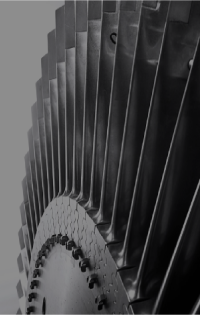

The large-scale transition of industries globally, from fossil fuels to thermal renewable fuel (referred to as green), has catalyzed a shift in business priorities. In this transforming landscape, sustainability has emerged as a top priority for industries across the world.

At Triveni Turbine Limited, with our innovative R&D eco-system, we are well positioned to address global sustainability requirements in this emerging energy transition environment through our comprehensive product and service offerings. The Company has also diversified into clean energy solutions by utilising thermal renewable fuels such as Waste Heat, Commercial & Industrial Waste, Municipal Waste & Biomass and Bagasse.

With ~80% of overall order booking coming from thermal renewable fuels, we continue to provide our customers solutions that can effectively reduce their carbon footprint, reinforcing our collective efforts towards a more sustainable future.

Driving Energy Efficiencies

Innovating & Leading the Energy Transition

-

sCO2 Turbines:

We are championing energy transition efforts through the development of sCO2-based power blocks. sCO2 technology offers itself as a higher efficiency & compact replacement to steam. Size reduction by a factor of five (5) can be expected with the sCO2 power blocks. In association with a renowned university (IISc), we have built a prototype of the sCO2 power block, the successful validation of which will allow the technology to progress to TRL 9 (TRL – Technology Readiness Level)

-

tCO2 Heat Pump & Cooling Skid

Current heating & cooling needs invariably rely on refrigerants that have the Global Warming Potential significantly higher than that of CO2. CO2 also offers itself as an environment-friendly & economical alternative to synthetic refrigerants. With these advantages in focus, we have built the tCO2 (Transcritical CO2) Heat Pump & Cooling Skids & successfully commercialized the technology.

-

Innovating for a Self-Sustaining Tomorrow

At the UN Climate Change Conference of the Parties (COP26), India committed itself to becoming a Net-Zero carbon emitter by 2070 and announced enhanced targets for renewable energy deployment and reduction in carbon emissions. This has emerged as a strong catalyst for increasing the domestic demand for renewable energy.

Led by our deep domain understanding, we continue to innovate products and solutions designed to meet the needs of customers across the world in the emerging areas of sustainable growth, particularly in the area of renewable energy. Nearly 80% of our business currently comes from non-fossil or renewable energy.

Innovating for a Self-Sustaining Tomorrow

At the UN Climate Change Conference of the Parties (COP26), India committed itself to become a Net-Zero carbon emitter by 2070 and announced enhanced targets for renewable energy deployment and reduction in carbon emissions. This has emerged as a strong catalyst for increasing the domestic demand for renewable energy.

Led by our deep domain understanding, we continue to innovate products and solutions designed to meet the needs of customers across the world in the emerging areas of sustainable growth, particularly in the area of renewable energy. Nearly 80%* of our business currently comes from non-fossil or renewable energy.

Continued Focus on Environmental, Social and Governance (ESG)

Contact Reach out to us