Basic Principles of Steam Turbine Operation

When it comes to electricity generation, one of the most crucial systems in use today is the steam turbine. For over a century, steam turbines have played a central role in driving advancements in both industrial and power generation sectors. The efficiency and reliability of these machines make them indispensable in various sectors, from power plants to manufacturing industries. However, understanding the steam turbine working principle can be complex for those unfamiliar with these mechanical marvels.

This blog aims to simplify the complex steam turbine working principle and mechanics. It will also clarify the workings of a steam turbine and its role in power generation.

The Steam Turbine Working Principle: A Foundation in Thermodynamics

At its core, the principle of steam turbine operation is grounded in thermodynamics. Steam turbines turn pressurized steam into mechanical energy. This mechanical energy is then converted into electrical energy in power plants. However, how does this process work?

In a steam power plant, water is heated in a boiler, creating steam. This steam is then directed towards the steam turbine at high pressure. The rapid expansion of steam as it flows through the steam turbine blades creates the rotational motion required to generate mechanical energy. This mechanical energy can then be converted into electricity in a generator, making the steam power plant working process complete.

Key Components and How do They Contribute to Efficiency?

Understanding the workings of a steam turbine requires familiarity with its key components. Each part has a crucial role in the overall performance and efficiency of the steam turbine:

- Blades and Rotors: The blades are carefully engineered to ensure maximum efficiency in capturing energy from the steam. The rotor is connected to the blades, and this rotational motion ultimately drives the generator.

- Casing: The steam turbine casing holds the blades and rotors in place and contains the steam as it flows through the turbine.

- Shaft: The shaft connects the steam turbine to the generator. Its rotation is transferred directly to the generator, producing electricity.

- Condenser: After the steam passes through the steam turbine, it is condensed back into water and recycled to the boiler to produce more steam, continuing the cycle.

Each of these components works in harmony to ensure the steam turbine operates smoothly and efficiently, maintaining a steady supply of power.

The Role of Steam Pressure and Temperature

The operating principle of a steam turbine is based on thermodynamics. When high-pressure steam enters the turbine, it rapidly expands and loses heat. This heat loss causes the turbine blades to rotate, which in turn drives the rotor. Furthermore, the temperature at which the steam condenses in the condenser plays a crucial role in determining the overall efficiency of the steam turbine.

How Steam Expansion Drives Rotation?

This expansion process is governed by the laws of thermodynamics, ensuring that energy is consistently transferred from the steam to the turbine. The rotational motion generated by this transfer of energy is what ultimately drives the mechanical power of the steam turbine.

Steam Flow Rate and Its Importance

Another key factor in the steam turbine working principle is the steam flow rate. The rate at which steam flows through the steam turbine affects its ability to maintain constant rotational speed and power output. A consistent flow ensures the smooth operation of the steam turbine and prevents fluctuations in energy production.

Optimizing the flow rate is essential for steam turbine efficiency, as it directly impacts both the amount of energy transferred and the wear and tear on the steam turbine blades. By carefully monitoring and adjusting the steam flow rate, operators can ensure consistent performance in a steam power plant environment.

Practical Considerations in Steam Turbine Operation

Operating a steam turbine efficiently requires more than just understanding the mechanics; it involves addressing practical considerations such as regular maintenance and monitoring. Over time, the high-speed rotation and high-temperature steam can cause erosion and wear and tear on the blades.

To ensure a long operational lifespan, it is essential to inspect the blades regularly and make repairs when necessary. Furthermore, steam quality must be controlled to prevent impurities that can cause damage to the steam turbine’s components.

That’s why we at Triveni Turbines provide helpful support through our after-sales services. We deliver high-performance steam turbines and ensure our customers receive ongoing maintenance and technical assistance.

Enhancing Efficiency: Advances in Steam Turbine Technology

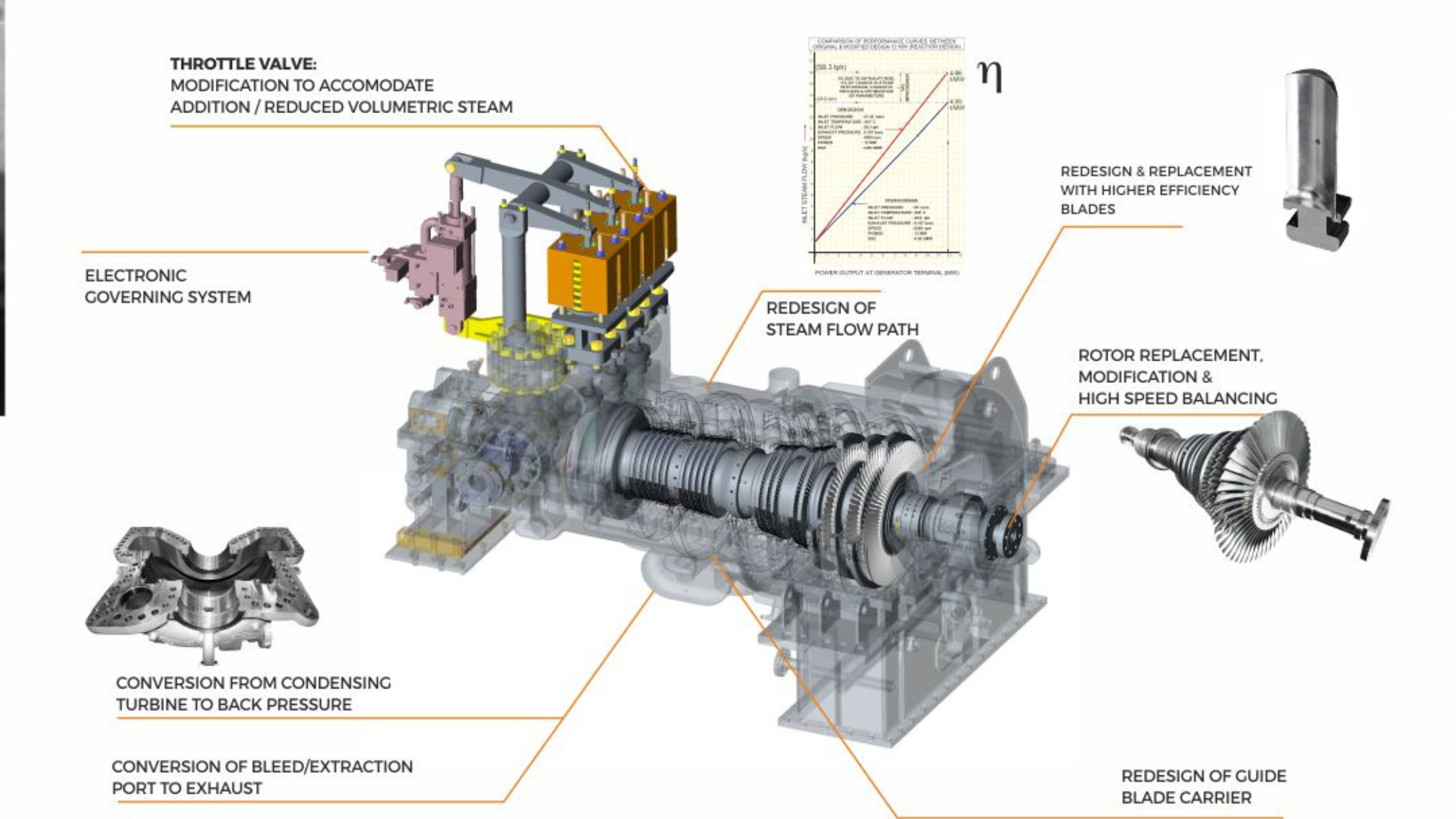

While the basic steam turbine working principle remains consistent, advancements in technology have made modern steam turbines more efficient than ever. Improved materials for steam turbine blades, more precise control systems, and innovations in steam generation have all contributed to their enhanced performance.

By continually refining the steam turbine working model, engineers can achieve better efficiency rates, reduce energy loss, and extend the lifespan of steam turbines. These improvements play a significant role in the global transition towards more sustainable and efficient energy production methods.

The Future of Steam Turbine Technology

The working of steam turbine power plants remains a crucial element of energy production worldwide. With continuous technological advancements and a focus on efficiency, steam turbines will continue to be vital for both industrial process and power generation needs.

At Triveni Turbines, we are proud to be at the forefront of steam turbine technology, providing advanced solutions that address the growing demands of today’s world. Our commitment to innovation and efficiency ensures that our steam turbines deliver optimal performance while reducing operational costs and environmental impact. Whether you are looking for reliable steam turbine solutions or seeking ways to enhance your existing setup, Triveni Turbines offers unparalleled expertise and support.