Steam Turbine Maintenance Best Practices

Steam turbines play a vital role in various power generation systems, including industrial captive power plants, independent power plants (IPPs), and geothermal facilities. They transform thermal energy into mechanical energy, which is then converted into electricity. However, like any advanced machinery, steam turbines demand regular maintenance to maintain peak performance, reduce downtime, and prolong their operational lifespan.

This blog will discuss the best practices for maintaining steam turbines, with a focus on preventive measures, operational monitoring, and troubleshooting techniques.

The Importance of Steam Turbine Maintenance

Understanding the importance of steam turbine maintenance goes beyond simply keeping the machinery operational; it has a direct impact on your bottom line. With Triveni Turbines’ high-efficiency steam turbines, manufacturers can achieve exceptional energy optimization, significantly cutting operational costs while supporting the transition to sustainable energy. Proper maintenance not only boosts performance but also contributes to eco-friendly initiatives by reducing waste and maximizing efficiency.

Regular maintenance helps prevent expensive steam turbine repair and ensures the reliability of your power generation system. With the growing global emphasis on sustainable and eco-friendly solutions, Triveni Turbines is a leader in reducing the carbon footprint of energy production.

Essential Steam Turbine Maintenance Strategies

Effective steam turbine maintenance relies on the application of key strategies that guarantee optimal performance and reliability. By focusing on routine inspections, vibration monitoring, and proper lubrication protocols, energy industries can significantly reduce downtime and extend the operational life of their steam turbines.

- Routine Inspections

Routine inspections form the foundation of effective steam turbine maintenance. Regular visual checks allow technicians to identify any signs of wear or irregularities, such as unusual vibrations or leaks. A steam turbine maintenance checklist can help structure these inspections, ensuring that no critical component is missed.

- Vibration Monitoring

Steam turbine maintenance procedure includes vibration monitoring. It is a crucial part of a comprehensive maintenance strategy. Advanced diagnostic tools can identify changes in vibration patterns, which often indicate underlying issues. By utilizing digital sensors and analytics, operators can detect problems early, enabling prompt interventions that help prevent serious damage or failure.

- Lubrication Protocols

Proper lubrication is essential for the longevity and efficiency of steam turbines. Establishing a lubrication protocol helps maintain optimal performance by reducing friction and wear between moving parts. Triveni Turbine’s innovative technology provides advanced lubrication systems that adapt to operational conditions, ensuring your steam turbine runs smoothly.

- Cleanliness is Key

Keeping the steam turbine and associated systems clean is critical for effective operation. Dust and debris can accumulate in various components, hindering performance and leading to overheating. Regular cleaning procedures should be incorporated into the steam turbine maintenance schedule to ensure all components operate efficiently.

Advanced Diagnostic Tools

In addition to basic maintenance practices, leveraging advanced diagnostic tools can significantly enhance steam turbine performance. Technologies such as thermography and acoustic emissions analysis offer real-time insights into steam turbine health. For example, thermography can detect thermal anomalies that may indicate impending failures, allowing for preemptive measures before issues escalate.

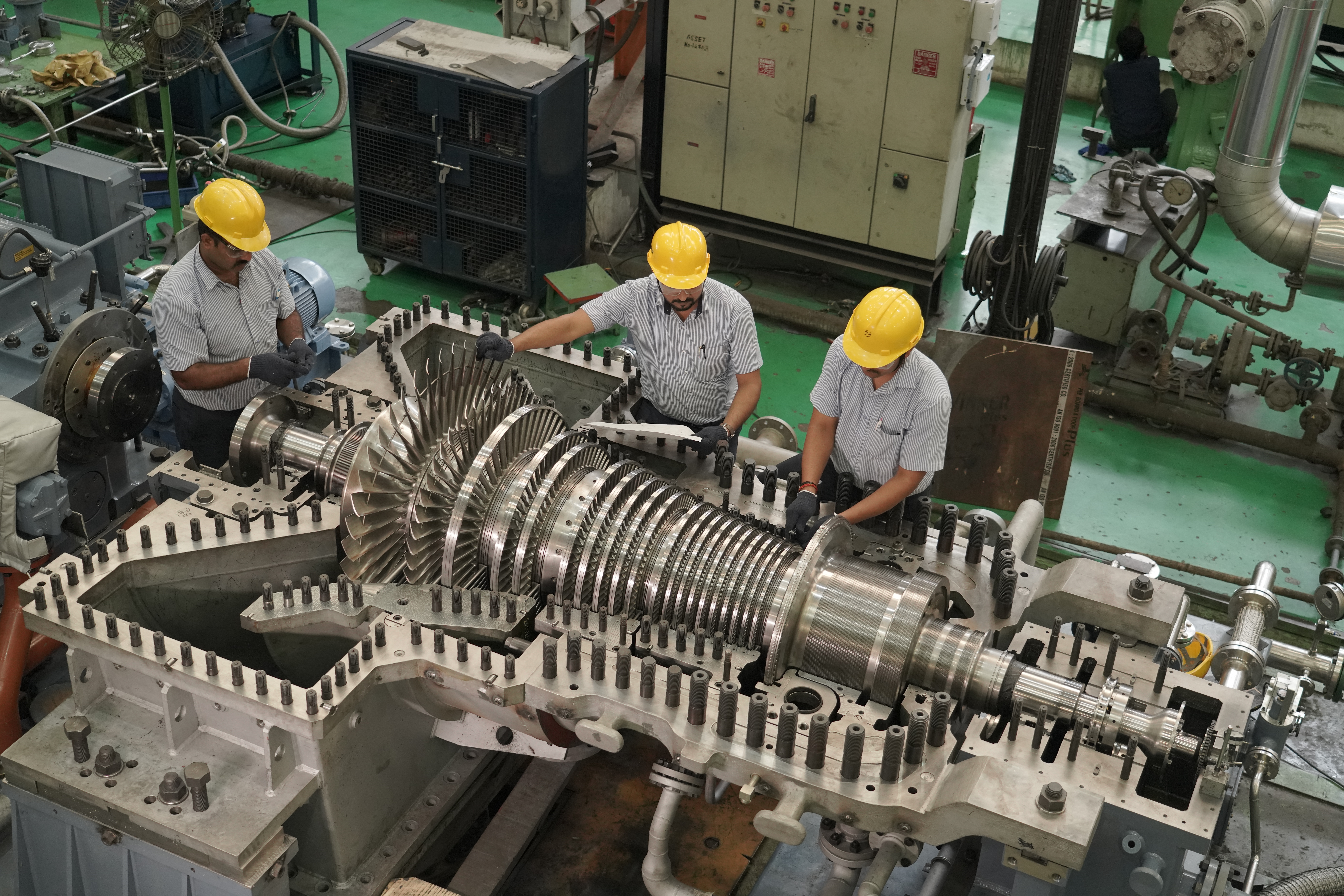

The Role of Skilled Technicians

The expertise of skilled technicians is invaluable in the realm of steam turbine maintenance. Our steam turbines are supported by a dedicated team of professionals who possess in-depth knowledge of the steam turbine overhauling procedure. Their expertise not only ensures adherence to best practices but also allows for customized steam turbine solutions tailored to your specific operational needs.

Investing in ongoing training for your maintenance team can lead to significant improvements in operational efficiency.

Benefits of a Well-maintained Schedule

Establishing a well-structured steam turbine maintenance schedule is crucial for maximizing steam turbine performance. Regular maintenance activities, such as inspections and repairs, should be strategically planned to minimize disruption to power generation.

Predictive maintenance techniques can provide valuable insights into when maintenance should occur, reducing unnecessary interventions. By utilizing data from monitoring systems, you can transition from a reactive maintenance approach to a more strategic, data-driven methodology.

The Value of Steam Turbine Maintenance Companies

Partnering with reputable steam turbine maintenance companies can significantly enhance your maintenance strategy. Companies like Triveni Turbines offer comprehensive aftermarket services that go beyond simple maintenance. Our robust support network guarantees that your steam turbines maintain peak performance, while also offering expert guidance on best practices for maintenance.

Selecting the right steam turbine maintenance provider is crucial to ensure your steam turbine gets the proper care and attention it requires. With Triveni Turbine’s commitment to innovative technology and customer-focused solutions, you can rest assured that your steam turbines will deliver reliable performance for many years.

Want to learn how Triveni Turbines can improve your steam turbine maintenance practices? Reach out to us today for customized solutions designed to meet your specific needs!