Steam turbine cycles and cycle design optimization

The extraction condensing turbine is able to change the electric power and the process steam flow independently by adjusting inlet steam flow and process steam flow. Adjustment of process steam flow is implemented by the extraction control valve. The turbine output is adjusted by the main control valve for inlet steam flow in conjunction with the LP turbine flow affected by the extraction control valve. That is to say, the extraction condensing turbine has both features of the condensing turbine and the back pressure turbine and has the capability to fulfilling both the requirements of the electric power supply and the process steam flow.

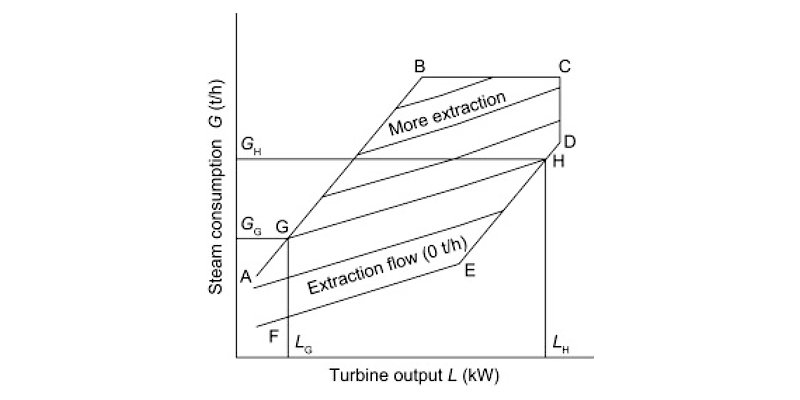

Fig. 2.15 shows a steam consumption diagram of the extraction condensing turbine. In this figure, the thick line F–E shows lower limit of operation under supplying process steam to facilities, line B–C shows the upper limit of inlet steam flow, thick line A–B shows the lower limit of the LP turbine flow, thick line D–E shows the upper limit of the low pressure turbine flow, and thick line CD shows upper limit of power output.