customercare@triveniturbines.com

Any Age,

Any Make

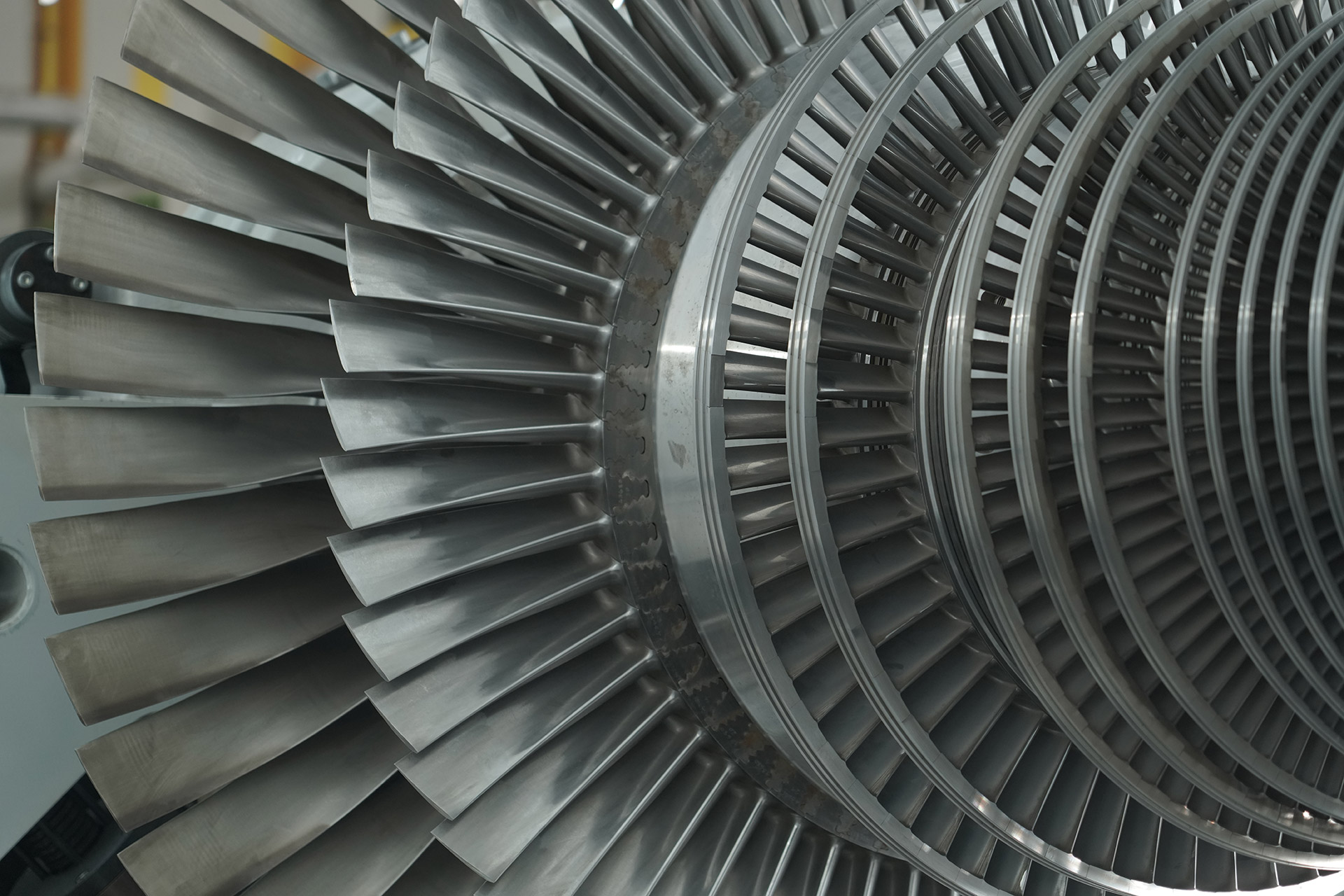

Industrial Steam Turbines

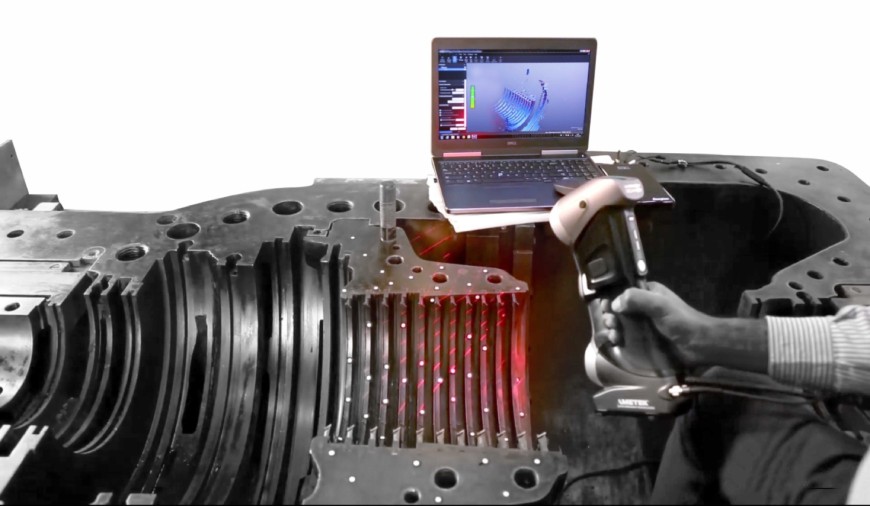

The aftermarket industrial steam turbine engineering and manufacturing team at Triveni REFURB have more than 50+ years of expertise and is skilled at offering creative, quick-fix solutions for steam turbines across all brands.

Our Services

Triveni REFURB is globally renowned, prioritizing efficiency advances like High Velocity Oxygen Fuel (HVOF) and laser cladding, backed by a dynamic design team, offering a comprehensive portfolio of overhauls, health evaluations, reverse engineering, and retrofits.

Contact Reach out to us