Any Age,

Any Make

Geothermal

Although geothermal power plant stations are more environmentally friendly than other energy stations, their steam contains large quantities of chloride, methane, sulfate, hydrogen sulfide and other such corrosive chemicals which tend to erode the surfaces of the internals more specifically the rotor, thus reducing life. This is a phenomenon seen across most Geothermal plants.

The most common issues faced on geothermal turbines are the frequent erosions of the blades and cavity formation which are results of impurities in the steam. This would lead to reduced efficiency, blade failures resulting in unexpected breakdowns. To assist our customers to overcome this issue, we redesign the internals within the existing housing and without any civil modification to extend the life of the turbine.

Services offered :-

- Efficiency restoration

- Up-gradation & Modernization

- Reverse Engineering / Re-Engineering & Spare Parts Supply

- Long-term Service Agreements (LTSA) / Overhauling / Operation and Maintenance / Residual Life Assessment (RLA) / Health Monitoring

- Electrical System Up-gradation

- Troubleshooting and Repair

- High-Speed Balancing

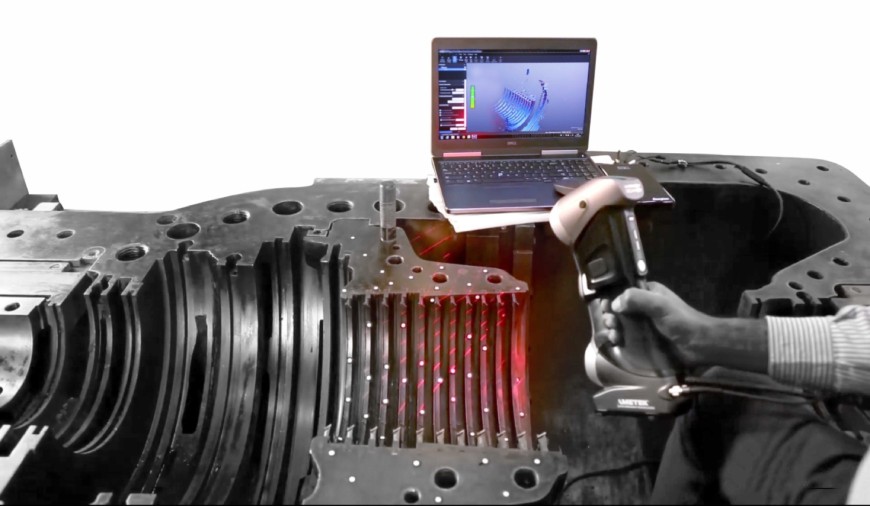

Triveni REFURB is globally renowned, prioritizing efficiency advances like High Velocity Oxygen Fuel (HVOF) and laser cladding, backed by a dynamic design team, offering a comprehensive portfolio of overhauls, health evaluations, reverse engineering, and retrofits.

Contact Reach out to us