mktg@triveniturbines.com

Powerful and

Responsible

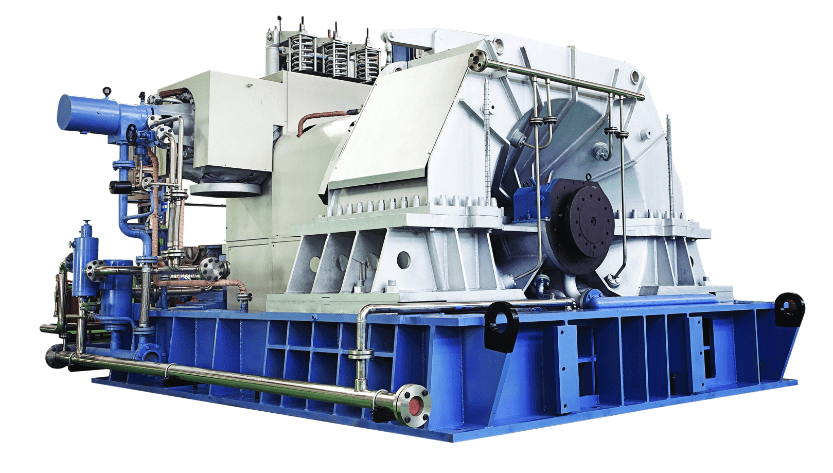

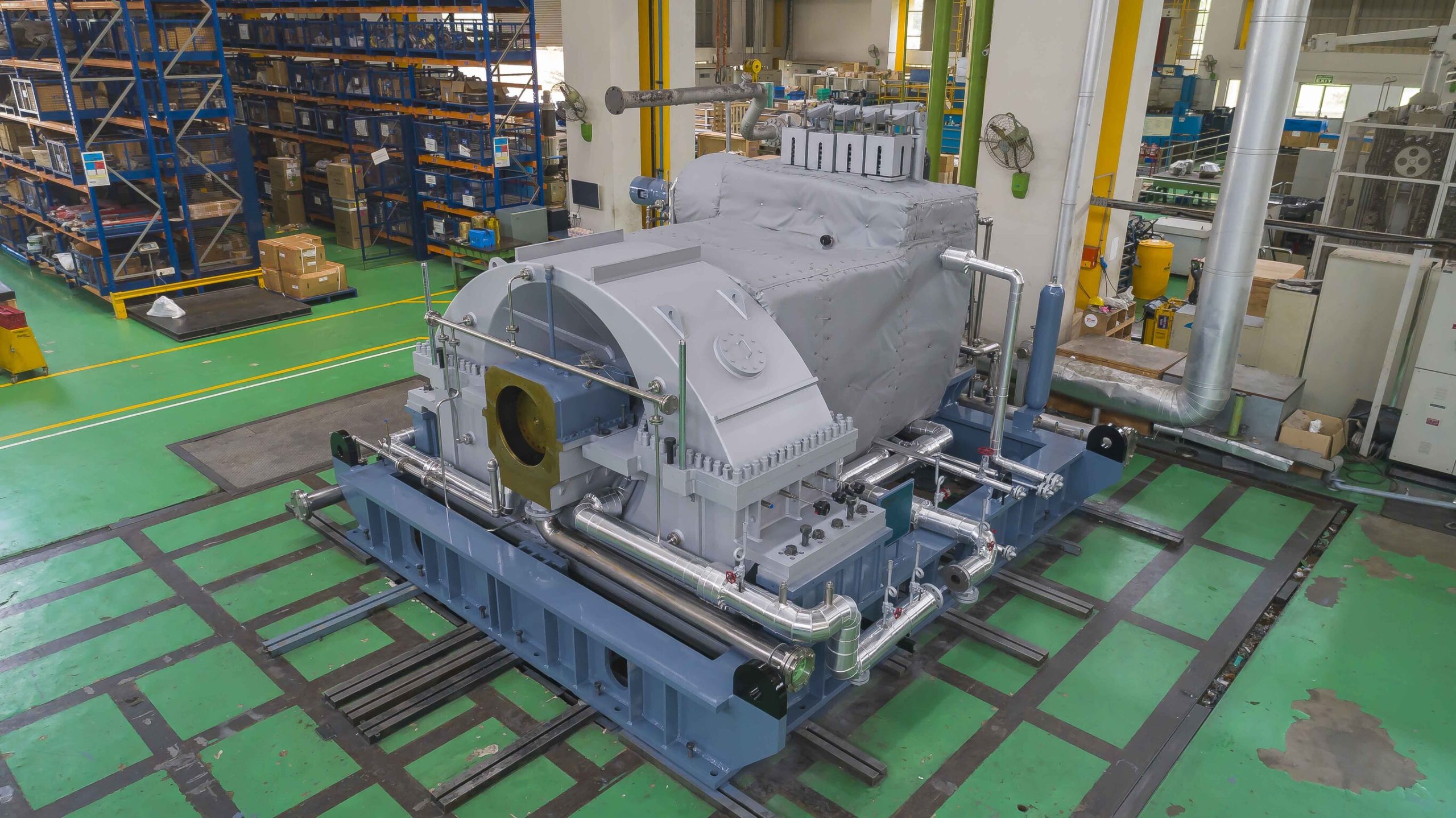

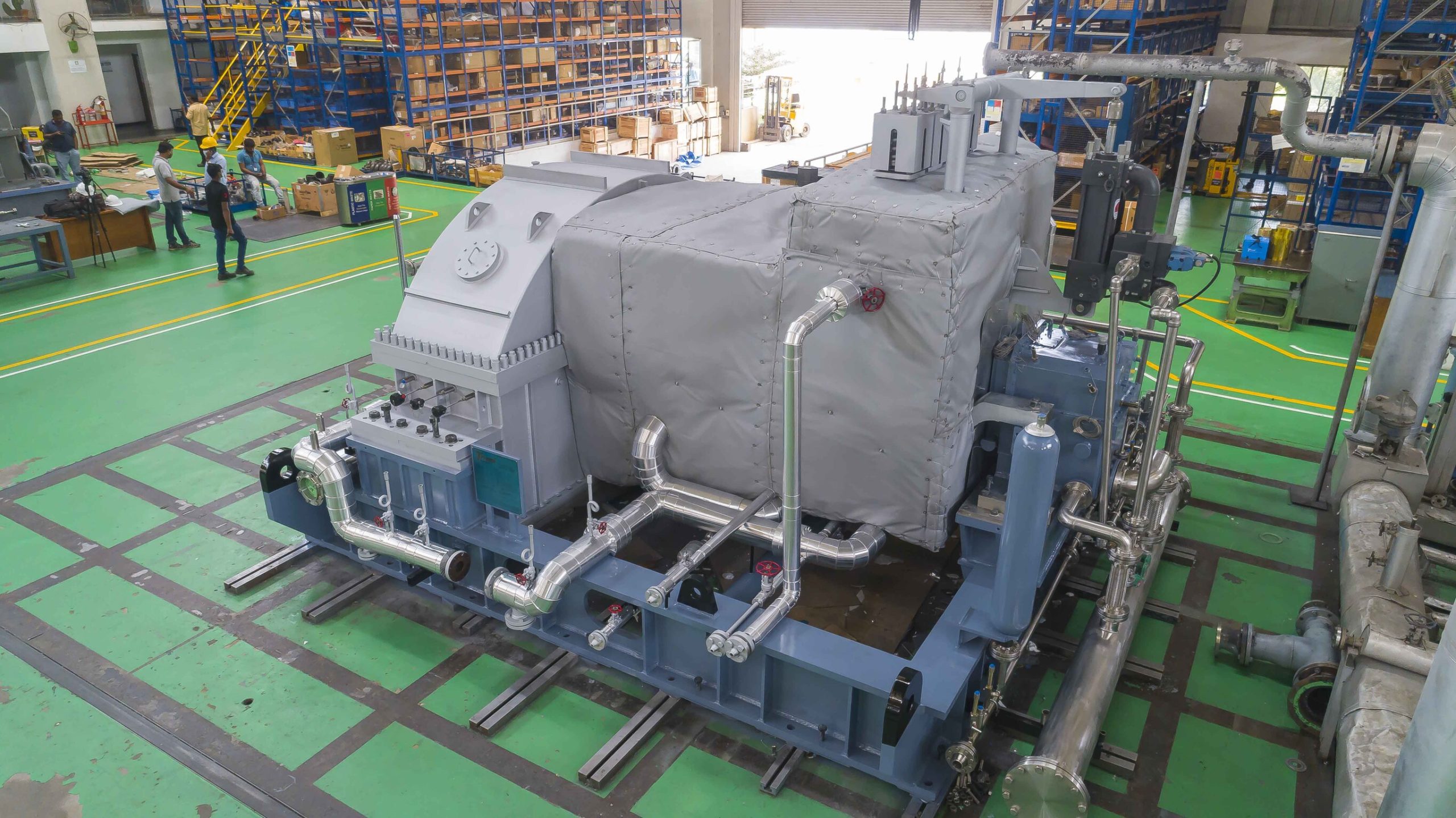

Condensing Steam Turbine

The condensing turbine can use the total energy of the inlet steam flow to a maximum extent. This type of steam turbine is used in power plants that are highly reliable to meet the power generation requirements.

Types of Condensing Steam Turbine :

- Straight Condensing

- Uncontrolled Extraction Condensing

- Controlled Extraction Condensing

- Double Extraction Condensing

- Injection Condensing

- Reheat Condensing

Key Design Features :

- Customised, efficient and compact design turbines with Integral oil tank.

- One/Multiple bleed provision at predetermined stage to extract steam.

- Horizontally split single cylinder turbine.

Key Design Features:

- Exhaust casing with provision for Radial/Axial exhaust orientation

- Hydraulically operating quick closing Stop and Emergency valve with integral stainless steel steam strainer

- Provision for single/double controlled extractions and multiple uncontrolled extraction points

Key Design Features:

- Flanged port/s provision on turbine casing for steam extraction/s

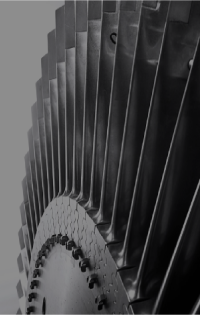

- Single piece forged alloy steel rotor - Dynamically balanced at full speed

- Alloy steel turbine blades shrouded/free standing

Key Design Features:

- Tilting pad type Journal & Thrust bearing 10. Turbine skid insulation Ceramic blanket type insulation (CAT-9)

- Electro Hydraulic Governing system as per NEMA with or without GRID synchronization

- Flexible couplings as per API 671

- Machine vibration monitoring and protection as per API 670

Technical Data :

- Power Output - Up to 100 MWe

- Inlet Steam Pressure - Up to 140 Bar (a)

- Inlet Steam Temperature - Up to 545 deg C

Typical Application :

- Combined Heat and Power

- Power Generation

- Mechanical Drives

Typical Segments :

- Steel

- Cement

- Sugar & Distillery

- Pulp & Paper

- Combined Cycle based IPPs

- Fertilizers

- Biomass based IPPs

Typical Segments :

- Food Processing

- Petroleum Refineries

- Chemicals

- Petrochemicals

- Oil & Gas (API)

- Waste to Energy based IPPs

- Coal based IPPs

Contact Reach out to us