mktg@triveniturbines.com

Efficient Power

Generation

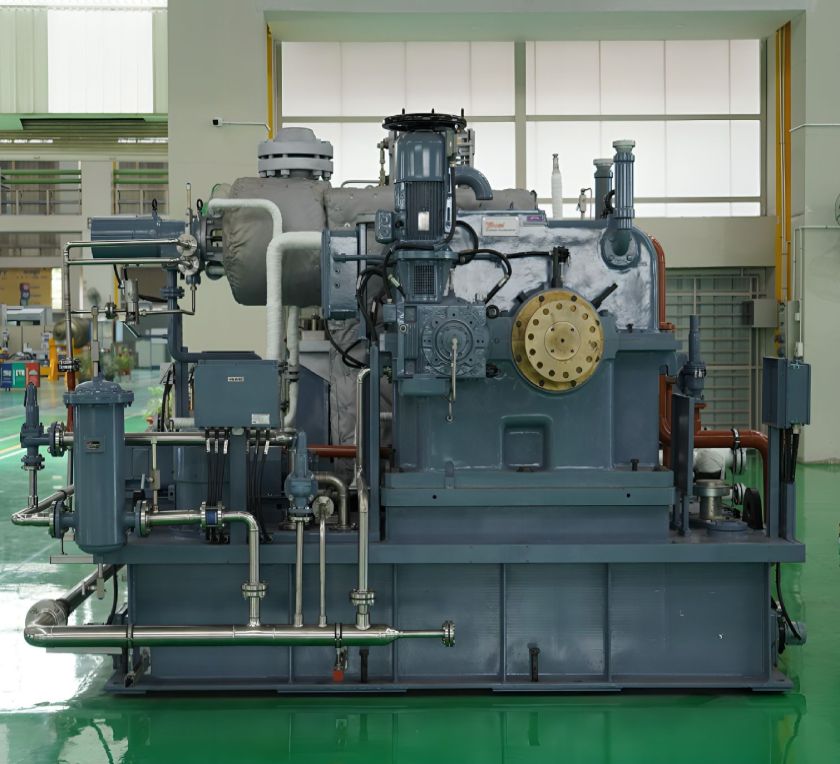

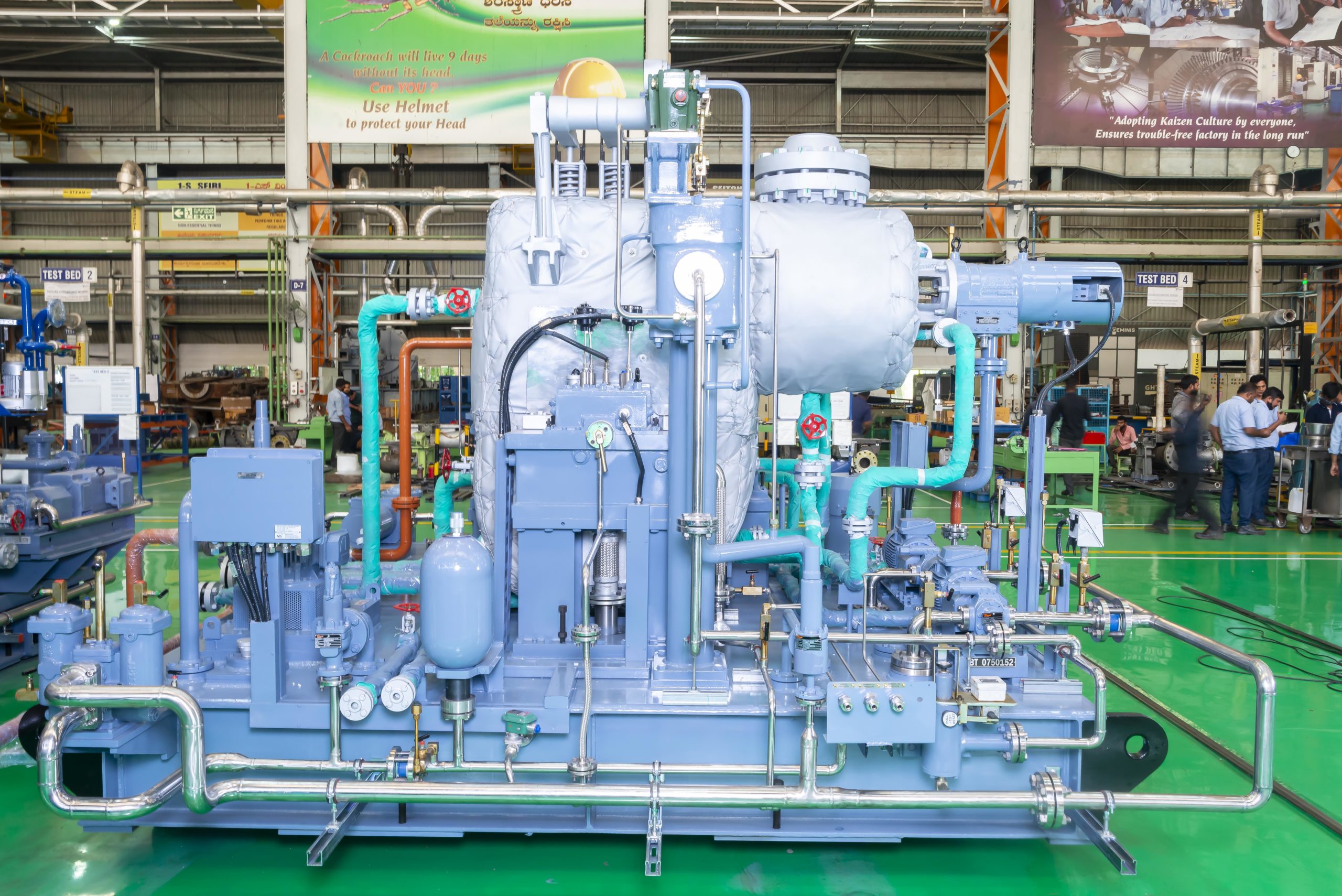

Backpressure Steam Turbine

The Backpressure Steam Turbine Generator (STG) is used for supplying process steam to the captive power producers. This type of steam turbine supplies not only electricity but also produce steam for various process requirements.

- Straight Uncontrolled Extraction

- Controlled Extraction

- Customised, efficient and compact design turbines: Single/Multi valve Impulse/Hybrid/Reaction types

- Horizontally split cast steel casing

- Hydraulically operating quick closing Stop and Emergency valve with integral stainless steel steam strainer

- Provision for single / double controlled extractions and multiple uncontrolled extraction points

- Flanged port/s provision on turbine casing for steam extraction/s

- Single piece forged alloy steel rotor - Dynamically balanced at full speed

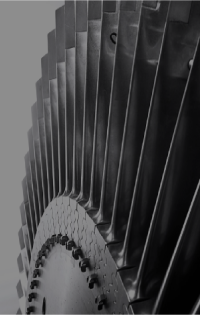

- Alloy steel turbine blades shrouded/free standing

- Tilting pad type Journal & Thrust bearing

- High efficiency sealing system for reduced steam leakages

- Electro Hydraulic Governing system as per NEMA

- Flexible couplings as per API 671

- Machine vibration monitoring and protection as per API 670

- Machine overspeed protection system (Mechnical and Electronic)

- Integral/separate lubrication and control oil systems as per manufacturer's standard/API 614

- Single/Double Helical single reduction gear box as per AGMA 6011 J14/API 613

- Power Output - Up to 100 MWe

- Inlet Steam Pressure - Up to 140 Bar (a)

- Inlet Steam Temperature - Up to 545 deg C

- Combined Heat and Power

- Mechanical Drives

- Parallel operation with Pressure Reducing & Desuperheating (PRDS)

- Sugar & Distillery

- Pulp & Paper

- Food Processing

- Palm Oil

- Petroleum Refineries

- Chemicals

- Petrochemicals

- Fertilizers

- Oil & Gas (API)

Contact Reach out to us