Innovating

Technology

Textile

Conservation and efficient utilisation of energy resources play a vital role in narrowing the gap between the demand and supply of energy. The next generation instrument for CO2 emissions cuts is the development of cogeneration as a renewable energy. Decentralised cogeneration is considered of paramount importance. The feasibility of installing cogeneration in a Textile mill with processing capability results in a payback period of 2 to 3 years.

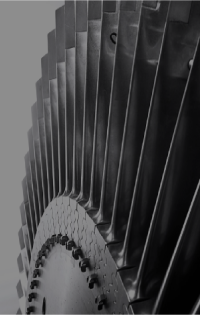

We aid the textile industry with comprehensive solutions to cope with the ever-increasing competition and altering trends, and our steam turbo generators produce consistent power and heat. Moreover, our steam turbines have low investment costs, and simple operation procedures and can be integrated easily into the plant’s process. They operate within various power ratios and do not require extensive maintenance.

Contact Reach out to us