Parts of Steam Turbine and Their Importance in Power Systems

Steam turbines are a cornerstone of contemporary power generation, converting thermal energy into mechanical energy, which is then converted into electrical power. Extensively used in thermal, nuclear, and industrial power plants, these machines are engineered to operate under high pressure and high temperature while ensuring consistent, reliable output.

Understanding the parts of a steam turbine is essential to see how each component controls steam flow, enables smooth rotation, and maintains structural integrity.

Examining the construction and function of turbine elements also helps improve efficiency, minimize operational risks, and extend service life.

Let’s understand how these critical components function together to ensure optimal performance in power systems.

7 Essential Parts of a Steam Turbine

The components of a steam turbine work in precise coordination. The following are the key parts of a steam turbine and their significance:

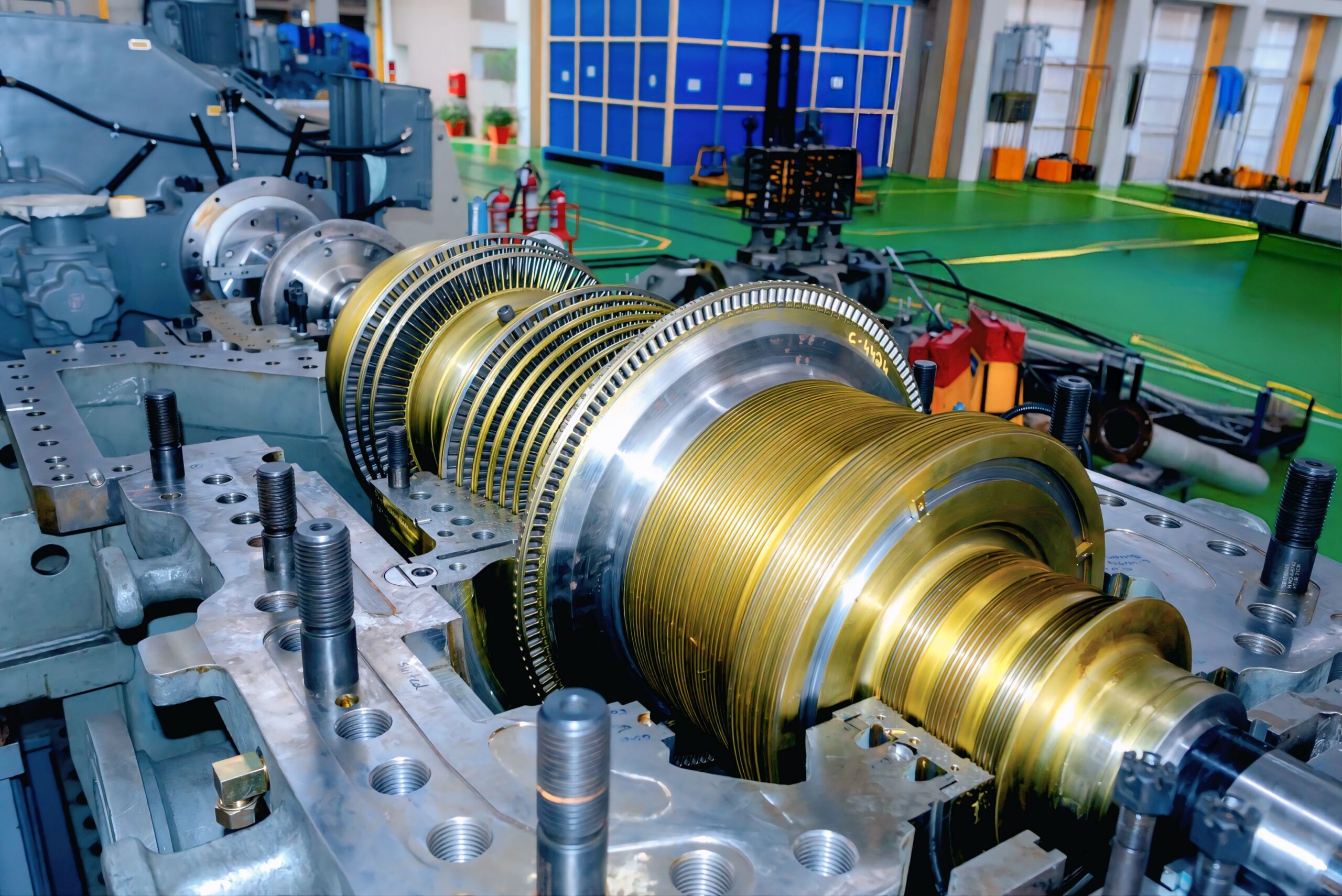

- Rotor

The rotor is the main part of a steam turbine, converting steam energy into mechanical motion. It carries the moving blades, transferring energy to the shaft, and is designed to withstand high thermal and centrifugal forces for stable operation.

Proper balancing minimizes vibration and wear, while the rotor’s alignment and durability directly affect turbine efficiency.

- Turbine Blades

Blades extract kinetic and pressure energy from steam and transfer it to the rotor. Stationary and moving blades guide steam flow efficiently, with their shape and material affecting durability and performance.

Proper alignment ensures smooth energy transfer, while blade design directly influences overall turbine efficiency and power output.

- Casing

The casing encloses the turbine assembly and contains high-pressure steam, serving as an essential part of a steam turbine. It provides structural integrity, protects internal components, and ensures the safety of personnel and surrounding equipment.

Proper insulation reduces energy losses and supports operational stability. The casing’s design enhances overall energy efficiency, and regular maintenance ensures the turbine continues to operate safely and reliably under demanding conditions.

- Nozzles or Stator

Nozzles direct steam onto the moving blades at optimal velocity and pressure, while stators guide steam for efficient energy transfer. These components are a critical part of a steam turbine, as their design minimizes turbulence and mechanical stress, improving overall performance. They also affect the turbine’s pressure drop and efficiency.

- Shaft

The shaft transmits mechanical energy from the rotor to the generator and is a central part of a steam turbine. Proper alignment and material strength are essential for uninterrupted operation.

It must endure rotational and thermal stresses, and lubrication prevents wear and damage. The shaft ensures a seamless connection between the turbine’s mechanical motion and the generation of electricity.

- Bearings

Bearings support the shaft and reduce friction during high-speed rotation, maintaining stability and preventing vibrations. Their design allows them to withstand operational stresses over extended periods.

Proper lubrication and regular inspection prevent premature wear, making bearings essential for smooth, safe, and reliable turbine operation.

- Governor System

The governor regulates steam flow according to load demand and maintains turbine speed. Modern systems allow precise control for efficiency and adapt to load fluctuations while maintaining output.

At Triveni Turbines, long-term reliability is achieved by integrating precision manufacturing, carefully selected materials, and lifecycle-focused design practices into every multi-stage turbine.

Ensure Reliable Steam Turbine Performance

The performance and longevity of a power system depend on the quality and maintenance of its steam turbine components. Engineers and plant operators must prioritize precision-engineered parts, including rotors, blades, bearings, and control systems, to ensure maximum efficiency and minimal downtime.

Investing in high-quality turbine components reduces operational risks, improves energy output, and enhances overall system reliability. By adopting best practices in monitoring, inspection, and maintenance, professionals can safeguard plant performance while meeting growing energy demands.

At Triveni Turbines, advanced materials, rigorous testing, and innovative design ensure that selecting trusted components is key to long-term operational excellence and sustainable power generation.