How to Choose the Best Steam Turbine Blades for Your Power Plant?

Optimizing power generation in industrial and utility power plants depends heavily on selecting the right steam turbine blades. The efficiency, performance, and durability of a steam turbine are directly influenced by the quality of its components—especially the blades.

Whether managing an industrial captive power plant, an independent power producer (IPP), or a geothermal facility, choosing the appropriate turbine blades is essential for achieving optimal performance. A thorough understanding of these factors ensures long term efficiency and reliability in your power generation system.

Key Considerations for Selecting Steam Turbine Blades

Let’s take a closer look at the key considerations for selecting steam turbine blades that best suit your power plant’s needs.

- Material Selection

The material of steam turbine blades plays a significant role in the blade’s ability to withstand the high temperatures and pressures found in steam turbines. Materials like stainless steel, titanium, and special alloys are commonly used due to their ability to resist corrosion, erosion, and thermal fatigue.

For environments with extreme conditions, such as oil and gas plants or geothermal power plants, selecting high-grade materials is essential to ensure reliability and longevity.

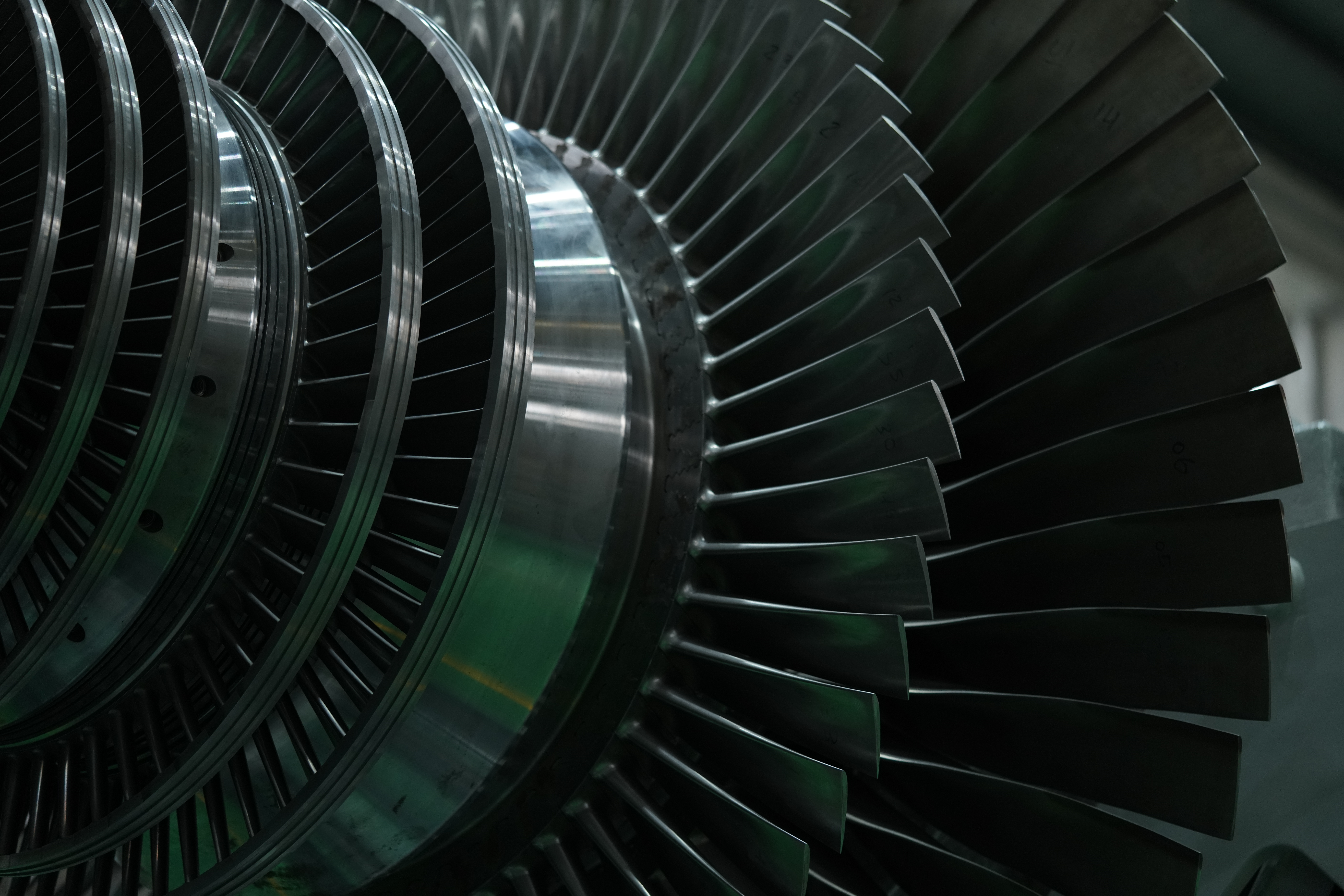

- Blade Design

Steam turbine blade design directly impacts the efficiency and durability of the steam turbine. The design must ensure optimal steam flow and energy conversion while minimizing wear and tear. The precision of the blade geometry and the surface finish are critical for reducing friction and ensuring smooth operation.

Additionally, advanced design techniques, such as 3D scanning and printing, are now employed to create customized steam turbine blades that fit perfectly with the unique specifications of your power plant.

- Steam Turbine Blade Types

Steam turbines use various types of blades; each designed for specific stages of the steam turbine. The three primary types of blades include low-pressure blades, intermediate-pressure blades, and high-pressure blades. The type of blade used depends on the specific steam conditions and power output requirements of your plant.

Low-pressure blades are designed to handle large volumes of steam at lower temperatures, while high-pressure blades are built for handling high-temperature, high-pressure steam. Selecting the right blade type ensures optimal energy conversion and helps prevent unnecessary wear.

- Efficiency and Energy Optimization

High-efficiency steam turbine blades play a vital role in reducing operational costs by enhancing the steam turbine’s overall efficiency. With the growing focus on sustainable power solutions, power plants must prioritize steam turbines that maximize energy output while minimizing energy loss.

- Maintenance and Aftermarket Services

Even the most advanced steam turbine blades require maintenance to maintain peak performance. Ensuring that your steam turbine blades are easy to inspect, clean, and replace is vital to keeping your plant running smoothly. Triveni Turbines offers comprehensive aftermarket services, including regular maintenance, performance enhancement solutions, and spare parts support.

By providing exceptional support throughout the steam turbine’s lifecycle, we ensure that your machine continues to operate with maximum efficiency, reducing downtime and boosting overall performance. Triveni Turbines offers high-efficiency and durable steam turbine blades that contribute to cost-effective power generation and reduced environmental impact.

We’re here to help you enhance your power generation system, improve efficiency, and reduce operational costs. Reach out to us today!