High-Pressure Turbines vs. Low-Pressure: Which One to Choose

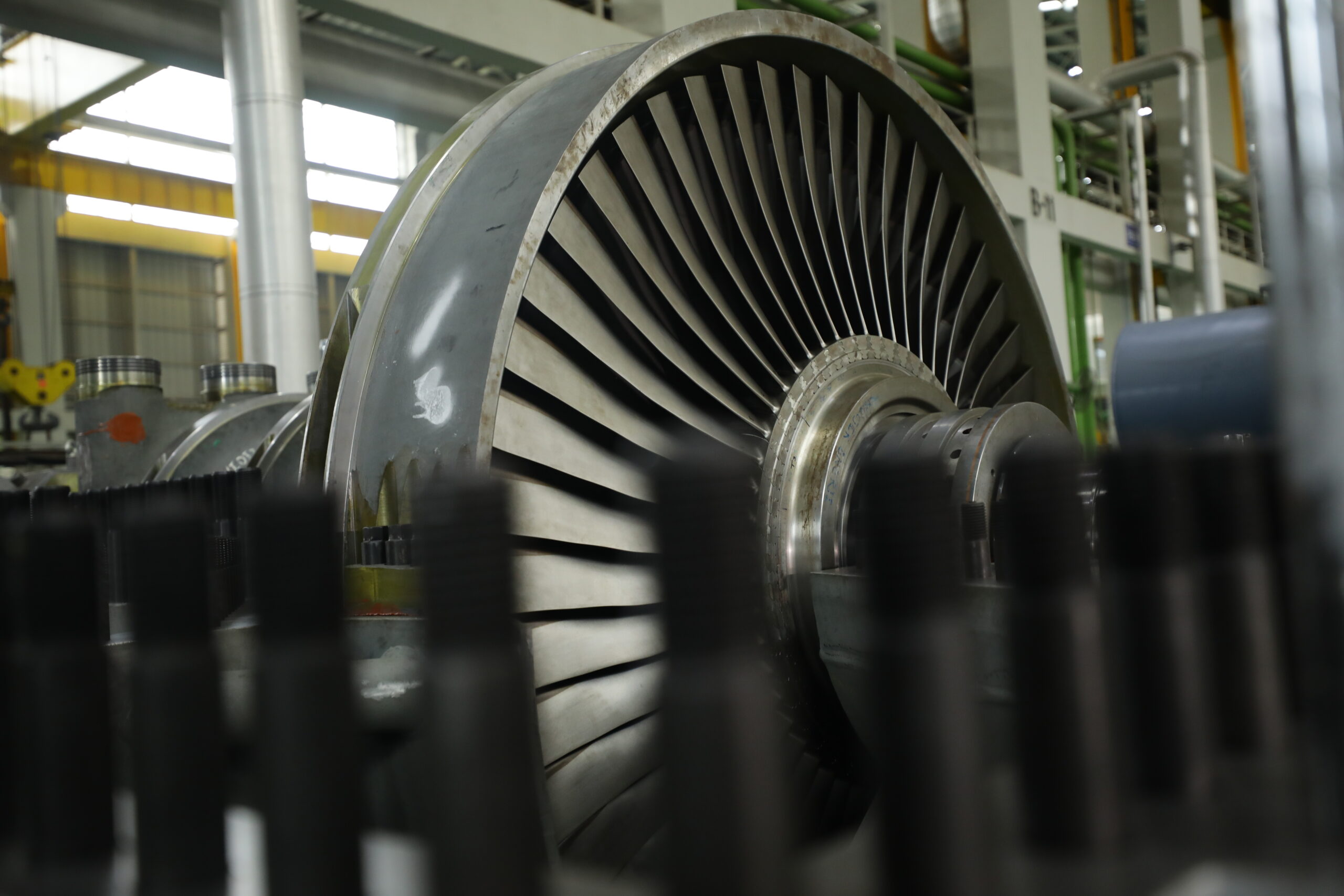

Steam turbines play a very important role in power generation, helping industries achieve cost-effective electricity production while optimizing efficiency. Whether it’s a high-pressure steam turbine or a low-pressure steam turbine, each serves a unique purpose in industrial operations.

A high-pressure steam turbine is designed for large-scale power generation, commonly used in utility power plants and geothermal power plants. These steam turbines operate at extremely high pressures, maximizing efficiency and output.

On the other hand, a low-pressure steam turbine generator is ideal for residual energy recovery, making it a preferred choice for industrial captive power plants and Independent Power Producers (IPPs) aiming for sustainable technology with a low carbon footprint.

Difference Between High-Pressure Steam Turbine and Low-Pressure Steam Turbine

| Feature | High-Pressure Steam Turbine | Low-Pressure Steam Turbine |

| Steam Pressure | Higher than 20 bar, up to 100 bar or more | Ranges from 1 to 10 bar |

| Efficiency | Designed for maximum efficiency at high pressures | Utilizes residual steam, enhancing energy optimization |

| Primary Use | Utility power plants, geothermal power plants, IPPs | Industrial captive power plants, oil & gas plants, IPPs |

| Energy Consumption | High steam temperatures for large-scale power generation | More economical, cost-effective energy use, reducing waste |

| Environmental Impact | Energy-intensive, higher emissions potential | Lower carbon footprint, contributes to energy transition |

| Applications | Best for large-scale, high-demand energy generation | Ideal for residual energy recovery and sustainable power |

| Benefits | High-efficiency, reliable power generation | Sustainable, cost-effective, energy optimization |

Why Choose High-Pressure Steam Turbines?

High-pressure steam turbines are ideal for large-scale power generation, offering maximum efficiency and output.

- Maximized Efficiency: High-pressure steam turbines are designed for maximum efficiency in environments where high steam pressure is available. This makes them ideal for utility power plants and geothermal power plants, where energy demand is high.

- Supporting Energy Demands: High-pressure steam turbines perform exceptionally well in high-demand energy generation setups, offering uninterrupted, reliable power to industries that cannot afford to have downtime. They are built to handle high-pressure steam efficiently, making them a vital part of a power generation system.

Why Choose Low-Pressure Steam Turbines?

Let’s discuss why you should consider using a low-pressure steam turbine.

- Cost-effective Power Generation: Low-pressure steam turbines excel at utilizing residual energy, making them an excellent choice for industrial captive power plants. By capturing the available steam and converting it to energy, these steam turbines provide cost-effective power generation with reduced energy consumption.

- Energy Optimization: For applications in oil and gas plants and smaller-scale IPPs, low-pressure steam turbines are perfect for energy optimization.

- Sustainability and Low Carbon Footprint: As industries transition to green technology, low-pressure steam turbines are a key player in supporting sustainable technology.

At Triveni Turbines, we are committed to providing cost-effective power generation through cutting-edge technology. Whether you need a high-pressure steam turbine for large-scale energy production or a low-pressure turbine for optimized energy use, our solutions offer the ideal combination of performance, sustainability, and cost effectiveness.

Get in touch with us today to discover more about our steam turbine solutions and how we can support your power plant in achieving sustainable power generation.