Mastering API 611: Compliance and Reliability for Steam Turbines

Steam turbines are the backbone of industrial power generation and mechanical drive applications, but ensuring their reliability requires strict adherence to international standards. Among these, API 611 stands out as the critical specification guiding the design, manufacturing, and testing of steam turbines.

Understanding API 611 requirements is essential for industries seeking dependable, high-performance turbines.

What is API 611?

The API 611 standard, developed by the American Petroleum Institute, provides detailed guidelines for API steam turbine design, materials, testing, and operational performance. This standard ensures that turbines operate safely under various steam conditions, handle different mechanical loads, and maintain structural integrity over time. Compliance with API 611 reduces downtime, enhances safety, and maximizes operational efficiency.

For turbine manufacturers, adhering to API 611 means delivering machinery that meets global benchmarks for reliability and performance. It involves meticulous attention to rotor design, bearing selection, vibration monitoring, and over-speed protection systems, all critical elements for an advanced API 611 steam turbine.

Key Requirements of API 611

API 611 sets forth several requirements that govern every stage of steam turbine development:

- Design and Materials: Components must withstand high-pressure, high-temperature steam. Material selection is critical to prevent erosion, corrosion, and fatigue.

- Rotor and Bearing Specifications: Built-up rotors or integral designs are specified, along with hydrodynamic journal bearings and anti-friction thrust bearings to ensure smooth operation.

- Vibration Monitoring: Accelerometers for casing vibration and optional shaft vibration probes help monitor mechanical stability.

- Over-speed Protection: Mechanical and electronic over-speed protection systems are mandatory to prevent catastrophic failures.

- Valve and Seal Systems: Combined trip and throttle valves, along with carbon ring or labyrinth seals, are specified for controlling steam flow and minimizing leakage.

These guidelines ensure that API 611 steam turbines deliver long-term operational reliability and maintain the integrity of all critical components.

Single Stage vs. Multi-stage API 611 Turbines

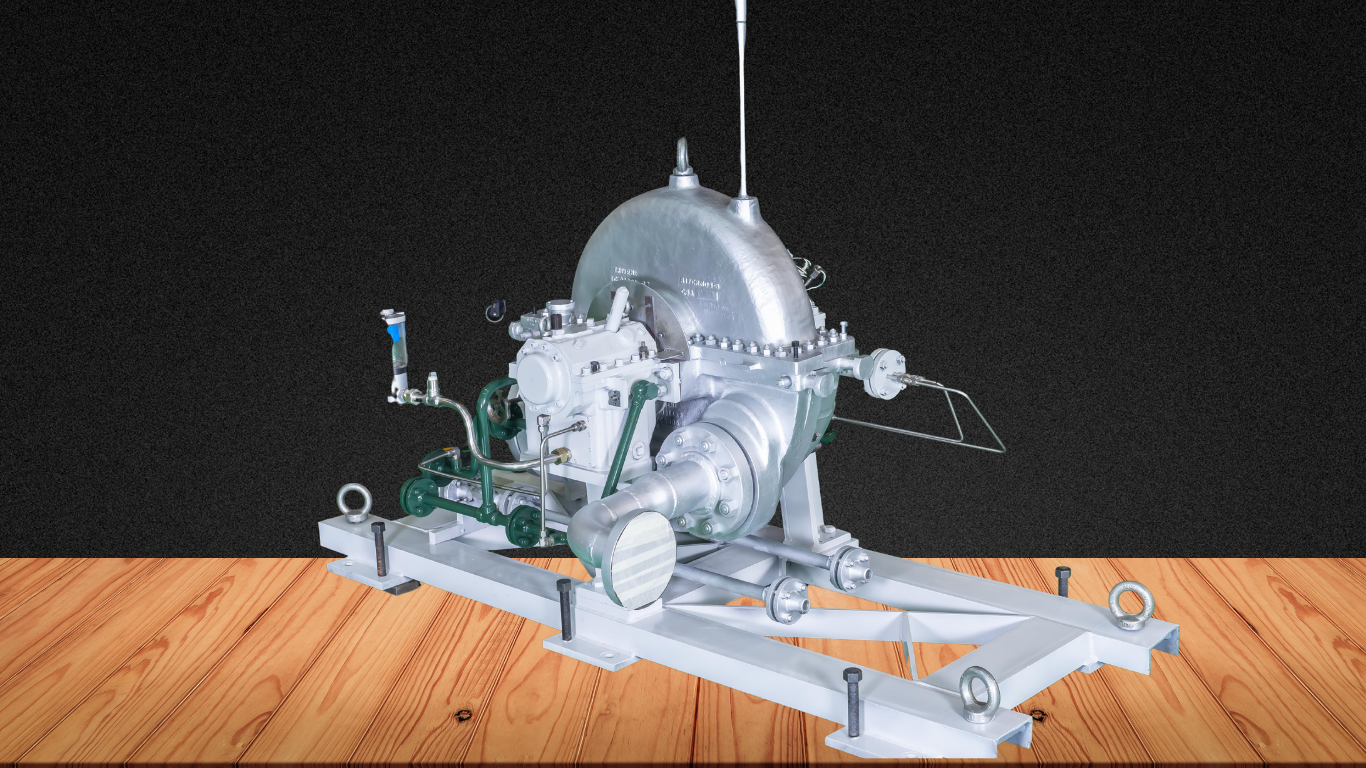

Triveni Turbines offers both single-stage and multi-stage turbines compliant with API 611, tailored to diverse industrial applications.

Single-stage turbines are designed for compact installations with a wide speed range and multiple operational steam conditions. Key features include:

- Built-up or optional integral rotors

- Mechanical and electronic speed governors with pneumatic or hydraulic actuators

- Hydrodynamic journal bearings and optional hydrodynamic thrust bearings

- Optional casing accelerometers and shaft vibration probes

- Combined trip and throttle valve systems for manual or auto start

These turbines provide a low-footprint, flexible solution suitable for mechanical drives and smaller power generation needs, while fully complying with API 611 standards.

Multi-stage turbines offer modular designs that provide greater flexibility for varied steam conditions and drive applications. They are engineered to meet both API 611 and API 612 standards, ensuring long-term reliability for industrial processes. Multi-stage turbines excel in:

- Extended uninterrupted operation

- Power generation and mechanical drive applications

- Adapting to diverse project specifications and steam conditions

The construction and adherence to API 611 requirements make these turbines a dependable choice for industries seeking high-efficiency, durable machinery.

Ensuring Compliance and Maximizing Reliability

Mastering API 611 compliance is not just about meeting standards; it’s about building turbines that last. We invest in advanced engineering, rigorous testing, and precise quality control to ensure every turbine meets or exceeds API 611 specifications.

From design to operation, these practices enhance component integrity, minimize downtime, and deliver consistent, reliable performance.

Peace of Mind with Industry-standard Compliance

For industries relying on steam turbines, API 611 compliance is the benchmark for safety, performance, and longevity. Triveni Turbines’ single-stage and multi-stage turbines exemplify this commitment, offering advanced designs, operational flexibility, and reliable support.

By choosing API 611 steam turbines, businesses can ensure efficiency, durability, and peace of mind in their power generation and drive applications.