R&D capabilities

Innovation edge

Digital infrastructure & transformation

Focus on AI & Automation (Internet of Things)

Our strong Research & Development (R&D) capabilities enable us to create high-quality, precision-engineered products. Our R&D teams are armed with the necessary expertise and experience to ensure product lifecycle performance and optimisation, supported by cost rationalisation. The teams are technologically and digitally empowered to deliver customer and sector-specific solutions. They are also equipped with state-of-the-art Computational Fluid Dynamics (CFD) software and Finite Element Analysis (FEA) platform. Latest software tools help them design and develop innovative products and solutions. High-tech testing facilities are used for design validation, thus ensuring total efficiency, safety and reliability, along with functional excellence. Our advanced R&D product programme has over 60 field proven models/variants, ideally suited to the varied needs of diverse customers across industries. The R&D function is supported by in-house testing and field validation programmes.

The Triveni R&D core

Experienced design team with structural, Aero domain experts

Proven modular building blocks extensively tested for product life cycle performance

Customer Capex and Opex optimisation with extensive operability benefits

Service and solutions focussed on turbine uptime maximisation

Association with world-renowned design houses and academia – Indian Institute of Science, Cambridge, Polimi, Impact Tech. (Lockheed Martin), Concepts NREC - USA

Innovative product development concepts, such as design to cost, QFD (Quality Function Deployment), FMEA (Failure Mode & Effects Analysis) techniques, Design of Experiments (DOE)

Advanced Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), Neural network-based algorithms employed for aero performance and product reliability maximisation

Customised Plant Engineering solutions with PLM (Product Lifecycle Management), SAP (Systems, Applications & Products), advanced Computer Aided Design and Computer Aided Engineering

Thrust on futuristic technologies, such as super critical CO2 power blocks & concentrated solar thermal applications

Leveraging R&D to propel efficiencies

During the year, we continued to upgrade our R&D capabilities not just in terms of rotating equipment technological expertise but also for steam turbine, flow path and computational fluid dynamics in terms of newer profiles of blades. These efforts have led to significant achievements in terms of efficiency enhancement across the entire turbine cycle, through multiple modules of development.

Continued research on super critical CO2 power blocks, focussed on reducing the cost of the installed system and boosting efficiency to enhance the turbine lifecycle value proposition.

In the combined cycle market segment, we are using a technology involving the bottoming cycle of a gas turbine or gas engine to take out waste heat and utilise it in a heat recovery steam generator to produce power through a steam turbine.

Overall augmentation of our Design and Development edge.

Development and commercialisation of API turbines.

Our aim, going forward, is to invest further in new areas of fluid dynamics and rotating equipment. The thrust will be on utilising the best of our abilities, both from a manufacturing perspective as well as from supply chain and management view. With our new-age products benchmarked to the world’s best and available at an affordable price point, we see our investments in R&D giving our Aftermarket and refurbishment capabilities a big leap in the coming years.

With innovation central to our customer-centric business model, we are continuously striving to transform ourselves into an organisation driven by Intellectual Property (IP). We are continually working on breakthrough technological development for new products as well as for new components in the system, which are all IP protected.

In the last 11 years, we have filed for protection of intellectual property rights over 130 pioneering products/solutions developed in-house. These include 60 patent filings and more than 180 industrial design registrations. As of March 31, 2021, we had been awarded 202 intellectual property rights across various jurisdiction, including India, the European Union and the United States of America.

Innovation

Leading Edge Technology

Leading Edge Technology

Enhancing performance by developing latest design tools and software like Turbo-machinery CFD tools, lateral & torsional rotor dynamics software

Superior Design

Superior Design

Maximising efficiency and reliability by enhancing steam turbine designs for higher inlet temperature & pressures

Total Customer Satisfaction

Total Customer Satisfaction

Delivering more to the customer to help them to achieve unhindered performance and power self-sufficiency at optimal cost

Cost-Efficiencies

Cost-Efficiencies

Higher efficiencies and lower cost in terms of ownership and operations

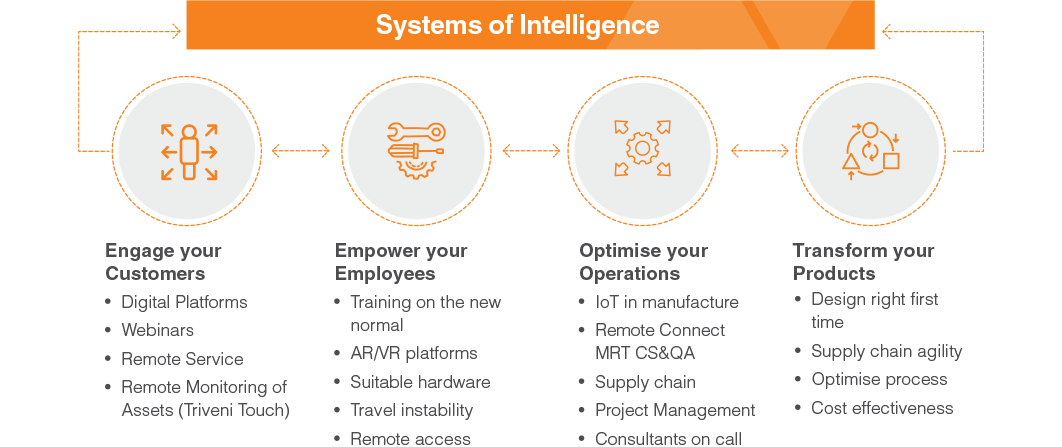

The digital platforms we had built early in the lockdown period of FY 21 helped us maintain a steady enquiry flow, while also enabling us to remain connected with our customers, employees and other stakeholders through the year. They complemented our efforts to bolster operational efficiencies, with our technology-enabled operations and reporting structures helping in tracking and capturing Overall Equipment Effectiveness (OEE).

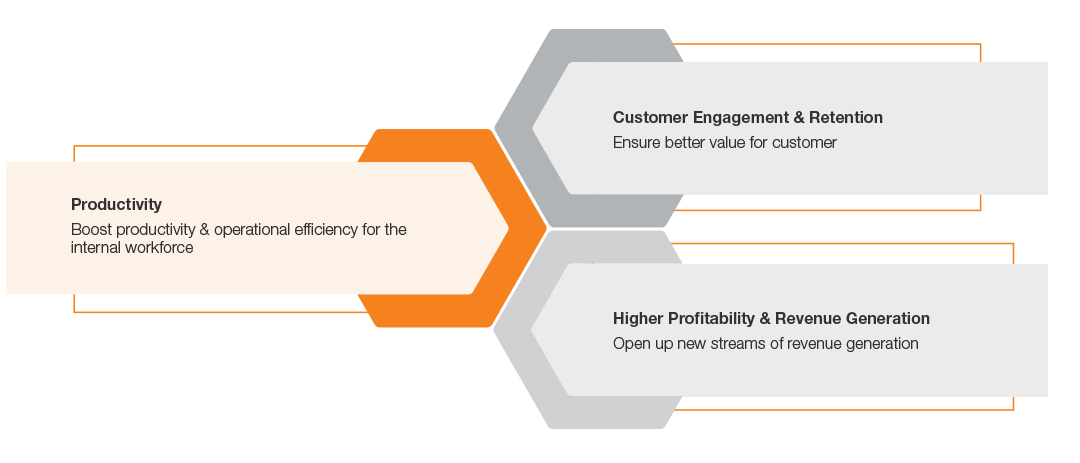

Digital Transformation

With digital becoming the new norm for operational excellence, we have strategically chosen to strengthen our digital capabilities, and empower our customers to meet the new and emerging business challenges. Our IT-enabled operations and reporting structures are helping in tracking and capturing Overall Equipment Effectiveness (OEE) and in boosting operator efficiency.

Our digital infrastructure encompasses the two key domains of:

We use the best-in-class digital technologies to facilitate seamless information flow through the entire value chain within the organisation - from sales and marketing to process planning, manufacturing, design, engineering, etc. - without human intervention. The transmission of data that results from use of cutting-edge digital technologies brought us closer to customers even during the pandemic. It gave us the ability to cater to customer requirements effectively even remotely, with lower costs and higher accuracy.

During the year, we went in for large-scale digitalisation of Manufacturing & Assembly parameters to ensure sustained quality, efficiency, reliability and safety.

Cloud First Initiative:

Cloud First Initiative:

We have successfully hosted around 80% applications on various Cloud platforms; we engaged a large IT Services company to develop Cloud-based application for better customer engagement and workforce productivity augmentation. We are continuously evaluating the application landscape and shall continue the digitalisation programme in FY 22.

Software & Automation suite:

Software & Automation suite:

We procured, and also developed in-house, a comprehensive suite of software and automation technologies for industrial applications, covering the entire lifecycle - from product design and production to Aftermarket services, as well as for commercial and financial applications. We shall continuously evaluate and benchmark our IT landscape with industry to see how we can leverage our strengths through use of best-in-class software products.

IOT & Industry 4.0:

IOT & Industry 4.0:

We embarked on our journey to embrace the Internet of Things (IoT) and Industry 4.0 to upgrade our various customer-centric applications with the latest technology, as per business requirements, with the aim of optimising costs and enhancing business productivity.

During the year, we enhanced data safety and strengthened home systems for our people who were working remotely, many of them on critical operations such as design, security and safety of network connectivity

What Equipped us to Adapt Seamlessly?

What Equipped us to Adapt Seamlessly?