The industrial energy landscape is transforming as rising demand intersects with the urgency to minimise costs and emissions. With an extensive portfolio and domain expertise, alongside investments in evolving design, research and engineering capabilities, we stand committed to supporting our customers and delivering lasting value in a new era.

Amidst growing concerns of climate change, environmental regulations are getting more stringent. Decarbonisation and efficiency are becoming an imperative in the global energy landscape.

An urgency to address the world’s energy trilemma of energy equity, security and sustainability.

Globally, the geopolitical tensions are escalating, driven by rising trade restrictions and heightened tariff risks.

Major economies are prioritising localised supply chains and indigenous manufacturing, especially in strategic energy sector to ensure resilience against disruptions.

India’s growing economy, driven by government’s focus on self-reliance and Make in India. This is fuelling industrial expansion, in an already energy-intensive sector.

Emerging energy-intensive sectors like AI/data centres and e-mobility are set to intensify electricity consumption and carbon emissions.

Captive power solutions, especially from thermal renewable sources, are becoming indispensable for industries. This will be key to ensuring their energy security, reducing operational costs and enabling waste-to-energy conversion to support low-carbon industrial processes.

In advanced economies, while energy demand is mostly stable, the energy-intensive industrial sector is instead focussed on efficiency improvements and clean energy adoption to mitigate the rising cost of capital and carbon emissions.

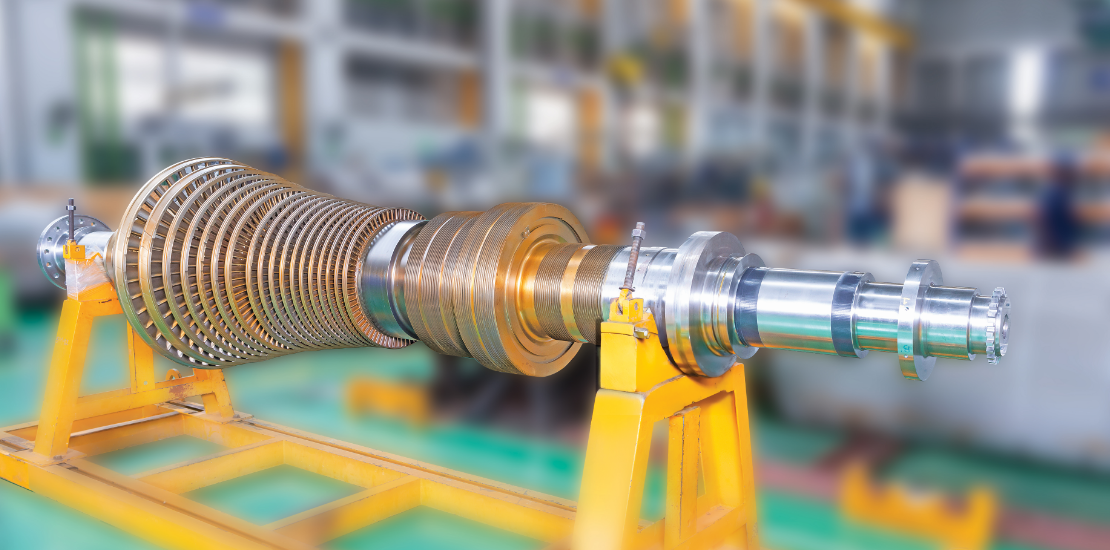

Industrial customers are increasingly investing in turbine solutions that set benchmarks for efficiency, robustness and uptime.

Globally, especially in the USA, a significant portion of traditional turbine infrastructure is reaching the end of operational life. Such systems pose a challenge to energy reliability and resilience, with risks of frequent breakdowns, lower efficiency, and increased maintenance costs.

The landscape necessitates companies to either invest in innovative, efficient solutions aligned with modern energy needs or undertake replacement and refurbishment of ageing systems.

We are a formidable player in industrial steam turbines, with an extensive portfolio of condensing and backpressure steam turbines. We offer these solutions across a wider power spectrum – a leadership position in the small power range (sub-30 MW) and a growing presence in the mid to high power range (30.1 to 100 MW).

The thermal renewables segment is gathering momentum globally, with its share in the global steam turbine market (up to 100 MW) increasing from 42% in 2014 to 73% in 2024.

TTL has taken a lead in this segment, having established a strong and diverse portfolio with specially-designed turbines capable of handling low-calorie heat. This includes:

for metals, cement and steel sector

for industrial and municipal waste treatment

covering bagasse, palm oil, residues, wood pellets, and rice husks

We have successfully penetrated the highly regulated and specification-driven API-compliant steam turbines segment. We have successfully registered with major oil & gas refineries and petrochemical complexes, and made breakthroughs with healthy ordering in FY 25 and a strong enquiry pipeline.

This segment offers steady business opportunities, driven by risk-averse customers who prefer long-term relations with trusted OEMs and consistent investment by oil majors in energy diversification.

Our local footprint across major geographies positions us to tap into refurbishment opportunities for the vast global base of turbine and other rotating equipment in these markets. This proximity to the market gives customers confidence in our long-term presence and responsive services.

A dedicated division, Triveni REFURB, leads this effort, providing comprehensive solutions ranging from health assessments to efficiency enhancement and process corrections, enhancing the life of ageing machinery. Additionally, this provides an opportunity to analyse diverse technologies and gain valuable insights that inform our product innovation efforts.

Our offices are strategically located across India, with exports primarily handled through our Bengaluru facility. Internationally, we maintain a strong presence in Europe, West Asia, Southeast Asia, the SADC region, and the USA, supported by local talent and ecosystems. This global footprint ensures timely service support across time zones, strengthening customer trust in our aftermarket capabilities.

We are proactively undertaking new products and new technology initiatives to diversify our portfolio across various energy transition products. This includes heat pumps, chillers, steam compressors, and gas expander turbines that use CO2 (supercritical and transcritical), air, or hydrocarbons for low-grade heat recovery.